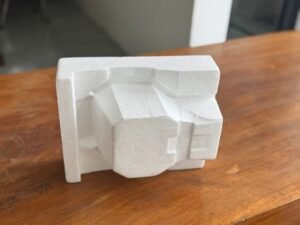

With modern production lines and precise production processes, EPS Central has completed the testing and quality assessment process, ready to mass produce foam products shaped according to its own molds.

1. Check input materials.

• Verify origin, composition, durability, purity…

• Ensure raw materials are in accordance with design and standards.

2. In-process Inspection.

• Monitor technical indicators in each stage.

• Ensure stable and correct technical process.

• Eliminate errors or defects that arise early.

3. Check product features and techniques.

• Measure dimensions and tolerances: compared to design drawings.

• Check durability and hardness to ensure products operate according to technical requirements.

4. Test according to international standards.

• Apply international standards ISO 9001:2015

5. Check safety and reliability.

• Evaluate the ability to operate in harsh real-life conditions.

• Simulate long-term durability (aging test, life cycle test).

6. Visual and aesthetic assessment.

• Check for defects in surface, color, texture, finishing, etc.

• Ensure consistency between product batches.

7. Overall assessment & defect analysis.

• Summary report of results.

• Analyze the cause of defects to improve the process (if any).

• Assess the level of compliance with the requirements of international partners.

The products meet strict technical standards from international partners, affirming the production capacity and quality commitment of EPS Central.

📍 EPS Central Region – Trusted partner of global businesses in the Central region of Vietnam.